- +0086 731-86398845

- sales@mascoonsewing.com

- turkey@mascoonsewing.com

- Mon to Fri 8:00 am to 18:00 pm

Double Head Silicone Machine MS-GJ200

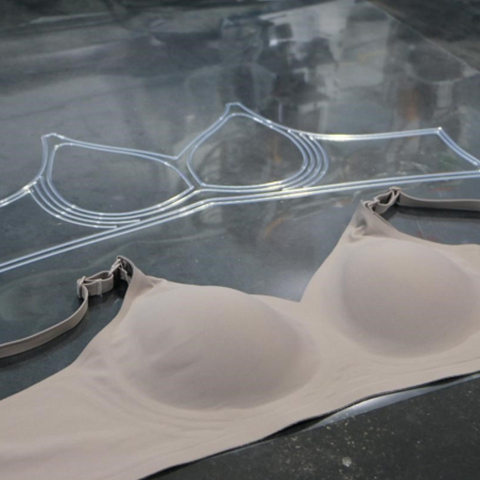

Underwear silicone dispense machine is a kind of professional equipment for the production of underwear silicone, it can process silicone material into various shapes of underwear pad, underwear pad, chest pad and other products. This machine has the characteristics of high efficiency, precision and stability, which can greatly improve the efficiency and quality of underwear production.

Voltage:220V Power:1.5Kw

Air Source:0.5Mpa Stroke:1000*800*60mm

HS Code:8424200000

-

What are the advantages of silicone underwear?

In the recent years, silicone underwear has become a new trend in the women's underwear market. Silicone underwear is favored by more and more women for its comfortable and natural wearing experience.

First, the comfort and breathability of silicone underwear will be its main selling point. Compared with traditional underwear, silicone underwear uses softer materials, which can not only fit the body better, but also allow the skin to breathe freely, reducing the feeling of humidity and sultry, thus improving the comfort of wearing.

-

Secondly, the shaping effect of silicone underwear will also become one of its important characteristics. Silicone underwear is made of special materials and designs, which can effectively shape the curves of a woman's body and make her figure more perfect. Compared with traditional shapewear, silicone underwear is more natural and comfortable, and will not cause too much pressure and burden on the body.This machine can do both round lines and flat strip in one garment.

-

Finally, the personalized and diversified silicone underwear will become its development trend. As women's demand for underwear becomes more and more diverse, silicone underwear will continue to launch more styles and colors to meet the needs and preferences of different women. At the same time, silicone underwear will also pay attention to personalized customized services, so that every woman can find the most suitable for their own silicone underwear, so that they are more confident and beautiful.

In short, the trend of silicone underwear will be comfort, shape, personalization and variety. With the continuous progress of technology and market changes, silicone underwear will become a strong momentum in the women's underwear market, bringing more comfortable, natural and beautiful wearing experience for women.

-

What are the features of our machine?

Multi-Function

①Flat strip、round line or both combined on one garment

Excellent Performance

①Max speed of 400mm/s on the XY axis and 300mm/s on the Z axis.

②Different widths on one garment. The min is 0.2mm and the max is 40mm.

③Internal booster pump and air storage tank to make sure the stable, uniform air source and adequate dispensing, suitable for mass production.

High Automation

①Adapt to DXF etc industrial drawing

②Automatically mixing silica gel without need to heat, welding cylinder design for convenient replacement.

High Precision

①Equipped with 5 gallon A/B barrel, 1:1 automatic mixing.

②Screw module configuration and a flat marble table contribute to high dispensing accuracy, stable movement.

Applicable range:Suitable for various of seamless underwear,lingerie.yoga pants and barbie pants etc

Technical Parameters

Model

MS-GJ200

Voltage

220V

Power

1.5Kw

Air Source

0.5Mpa

Barrel Temp

N/A

Jet Valve Temp

220-250℃

Stroke

1000*800*60mm

Motor

Servo

Jet Valve

2pcs

Working Station

1pc

Working Station

1pc

Net Weight

Glue Barrel

20kg/barrel

With Computer

N/A

Get a Quotation

Get latest price for seamless machines from Mascoon Sewing

Describe your needs in detail.

Get a Quotation from Mascoon Sewing

Get a quotation and we will reply within 24 hours.