- +0086 731-86398845

- sales@mascoonsewing.com

- turkey@mascoonsewing.com

- Mon to Fri 8:00 am to 18:00 pm

Multi-functional PUR+Silicone Dispensing Machine MS-DG400

With the development of technology, the underwear process is constantly upgraded and improved, and the underwear process combining pur glue and silicone is one of the highlights. This process combines the advantages of pur dispensing and silicone, not only to ensure the comfort and air permeability of underwear, but also to meet the needs of different consumers.

Voltage:220V Power:1.5Kw

PUR:300ml/can Silicone :20kg/barrel

HS Code:8424200000

-

What are the features of PUR and Silicone?

PUR glue is a strong adhesive with high viscosity, high strength, high transparency, high softness and high water resistance. It can complete curing in a short time with good heat and cold resistance which can be used for bonding various materials while silica gel is an elastic material with excellent softness, high temperature resistance, cold resistance and chemical corrosion resistance. It has excellent water absorption and air permeability, which can provide better comfort and air permeability.Now our Multi-functional PUR+Silicone Dispensing Machine MS-DG400 can achive this requirement.

-

The latest development for PUR+Silicone technology

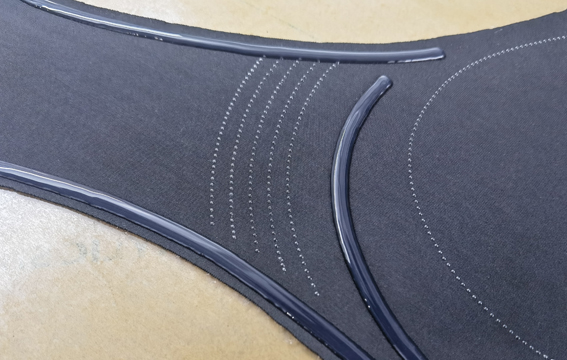

This process is to glue pur glue and silicone gel in different parts of the underwear. In the wings and back of the underwear, the use of pur glue for bonding can ensure the stability and support of the underwear. Use silicone for bonding on the bottom of the cup and shoulder straps to provide greater comfort and breathability.Through the combination of pur glue and silicone underwear process, the comfort of underwear, air permeability, stability and support have been fully guaranteed. At the same time, the process can also be customized according to the needs of different consumers, to meet the different needs and preferences of consumers.

In a word, pur dispensing and silicone combined underwear process is a kind of high-quality, high comfort, high air permeability and personalized customized underwear process, it will bring more opportunities and challenges for the development of the seamless underwear industry.

-

What are the machine features?

High Quality Material

-lScrew module configuration and a flat marble table contribute to high dispensing accuracy, stable movement.

-Anti-dust cover makes the working environment more clean.

-Seven inch touch screen,convenient for operation

Excellent Performance

-Different process available in one garment, quite suitable for sample development,saving the mold cost.

-lDifferent widths on one garment. The min is 0.2mm and the max is 40mm.

-lInternal booster pump and air storage tank to make sure the stable, uniform air source and adequate dispensing.

Multi-function

-Glue spot range could be accurate to 0.4-4mm max.

-Draw line width could be achieved to 1.5mm-30mm max.

-

Look at the complete video how it's working

Get a Quotation

Get latest price for seamless machines from Mascoon Sewing

Describe your needs in detail.

Get a Quotation from Mascoon Sewing

Get a quotation and we will reply within 24 hours.