- +0086 731-86398845

- sales@mascoonsewing.com

- turkey@mascoonsewing.com

- Mon to Fri 8:00 am to 18:00 pm

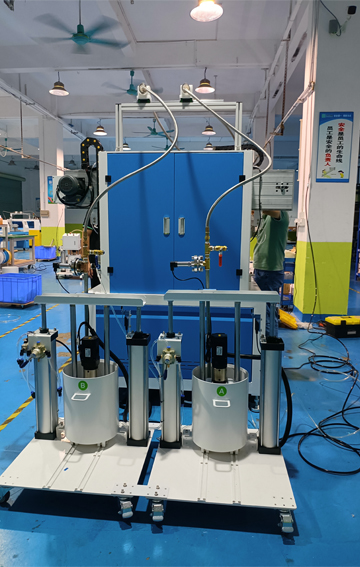

Silicone Silk Screen Printing Machine MS-214

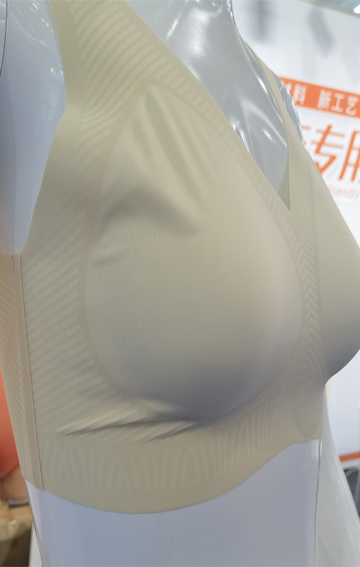

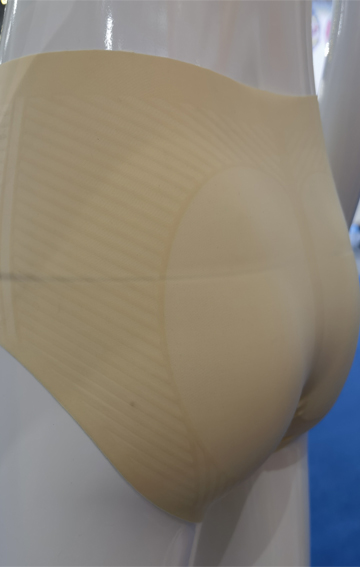

Underwear silicone silk printing machine is a kind of equipment used in the production of underwear, mainly used for underwear shoulder strap, edge and other parts coated with silicone, in order to increase the comfort and beauty of underwear. Compared with the traditional hand brush glue, underwear silicone silicone printing equipment has many advantages and trends.

Voltage:220V Power:3Kw

Air Source:0.5Kpa Machine Weight:580kg

HS Code:8443192290

-

Why we need to use the automatic silicone screen printing machine?

First of all, underwear silicone screen printing machine can improve production efficiency. Because the silicone rubber brush machine adopts automatic glue supply system, it can reduce manual intervention, reduce unnecessary waste and misoperation, so as to improve the work efficiency. In the same time, silicone silk screen printing machine can complete more work, bring more profits for enterprises.

-

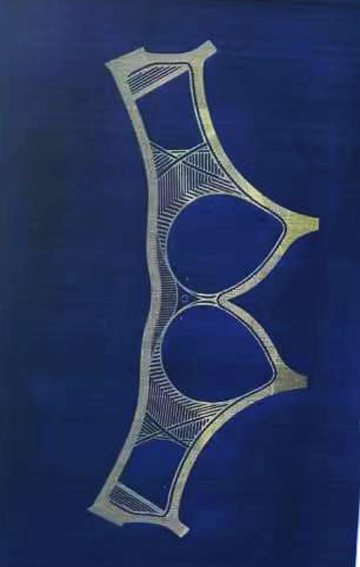

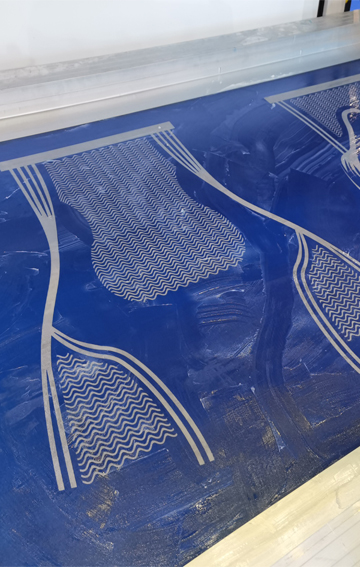

Secondly, underwear silicone screen printing machine can improve product quality. The silicone screen printing machine can ensure the uniformity and consistency of the glue coating, so as to improve the appearance quality and service life of the product. In the traditional manual brushing process, due to the interference of human factors, it often leads to uneven glue coating or too much or too little glue, affecting the quality of the product.

-

Finally, the trend of underwear silicone screen printing machine is automation and intelligence. With the continuous progress of science and technology, underwear silicone screen printing machine will be more and more intelligent, the use of more advanced automation technology, to achieve a more efficient, more stable, more accurate production process. At the same time, with people's attention to environmental protection and health, underwear silicone screen printing machine will also pay more and more attention to environmental protection and health, the use of more environmental protection and healthy materials and processes, to provide consumers with more safe and comfortable underwear products.

-

What the machine features?

①European standard module configuration

②Automatic glue mixing, and glue application, evenly proportioned

③The amount of glue can be adjusted, timed glue application

④Brushing result: no bubble, even thickness of glue

⑤A/B ratio monitoring to avoid uneven glue ratio

⑥Integrated reflux device, suitable for various thin and thick glue matching

Technical Parameters

Voltage

220V

Power

3Kw

Air Source

0.5Mpa

Net Weight

580kg

A/B Silicone Barrel

20kg/barrel

Machine Size

152*119*170cm

Printing Stroke

70*100cm

HS Code

8443192290

Get a Quotation

Get latest price for seamless machines from Mascoon Sewing

Describe your needs in detail.

Get a Quotation from Mascoon Sewing

Get a quotation and we will reply within 24 hours.